In modern manufacturing, consistency and precision are key to achieving durable and reliable welded joints. Spot welding has long been a preferred method in various industries because of its speed, cost-efficiency, and ability to join thin sheets of metal without the need for additional materials. However, the quality of the weld is heavily influenced by time control. This is where the adjustable welding time pedal spot welding machine becomes an essential tool. By allowing operators to control welding duration with accuracy, it ensures stable results and minimizes defects that could compromise product integrity.

Understanding the Role of Welding Time in Spot Welding

Spot welding relies on applying pressure and heat through electrodes to fuse two metal sheets. The welding time determines how much heat is delivered to the joint. If the time is too short, the weld will be weak; if it is too long, the material may burn or deform. Achieving the correct balance is critical.

An adjustable welding time pedal spot welding machine solves this problem by giving the operator precise control over welding duration. Unlike traditional machines with fixed settings, this design lets users fine-tune welding time for different materials, thicknesses, and production needs. This adaptability ensures that each weld is uniform and durable.

Why Adjustable Welding Time Ensures Consistent Quality

Consistency is a cornerstone of quality control. Adjustable time settings help avoid the common issues that arise in spot welding:

- Insufficient bonding when welding time is too short.

- Overheating and burn-through when welding time is excessive.

- Uneven welds caused by material variations.

With adjustable time, manufacturers can set exact parameters for each production run. This ensures repeatable performance , reduces rework, and helps maintain compliance with industrial standards. For wholesalers, this feature translates into higher reliability and lower return rates from end users.

Advantages of Pedal Operation in Spot Welding Machines

Another defining feature of the adjustable welding time pedal spot welding machine is its pedal-controlled operation. Pedal use offers greater control, improved safety, and ergonomic benefits :

- Hands-free control: Operators can focus on positioning the materials while activating the weld with their foot.

- Enhanced precision: The pedal allows smoother initiation and termination of the weld cycle.

- Operator comfort: Pedal operation reduces fatigue, which is particularly valuable in high-volume production.

By combining pedal operation with adjustable time, this machine provides a dual advantage: better weld quality and improved operator experience.

Applications Across Industries

The versatility of an adjustable welding time pedal spot welding machine makes it suitable for a wide range of industries. Some of the most common applications include:

| Industry | Typical Applications | Benefits of Adjustable Time |

| Automotive | Body panels, frames, brackets | Strong, repeatable welds on varying sheet thicknesses |

| Electronics | Battery packs, small enclosures | Precision for delicate materials |

| Metal Furniture | Frames, joints, reinforcements | Reliable connections without excess heat |

| Appliances | Casings, internal components | Uniform welds for long-lasting durability |

| Sheet Metal Fabrication | Custom parts, structural joints | Flexibility to adjust for different projects |

Buyers in these industries value the ability to adapt welding parameters , which leads to better product quality and fewer defects during mass production.

Key Benefits for Wholesalers and Buyers

Investing in an adjustable welding time pedal spot welding machine provides multiple benefits:

- Consistent Output Quality – Ensures uniform weld strength across production batches.

- Versatility – Suitable for a wide range of materials and thicknesses.

- Reduced Defects – Minimizes issues such as weak welds or overheating.

- Operational Efficiency – Pedal operation improves workflow and reduces downtime.

- Cost Savings – Less material waste and rework lower overall operating costs.

For wholesalers, these advantages create a strong value proposition when presenting the machine to potential buyers, especially in industries where welding precision is critical.

Factors to Consider When Buying

When choosing an adjustable welding time pedal spot welding machine , buyers should evaluate several important factors:

- Welding capacity: Ensure the machine supports the material thickness and type you require.

- Time adjustment range: Look for flexibility in welding duration to accommodate different projects.

- Pedal design and ergonomics: Comfort and durability are vital for operator satisfaction.

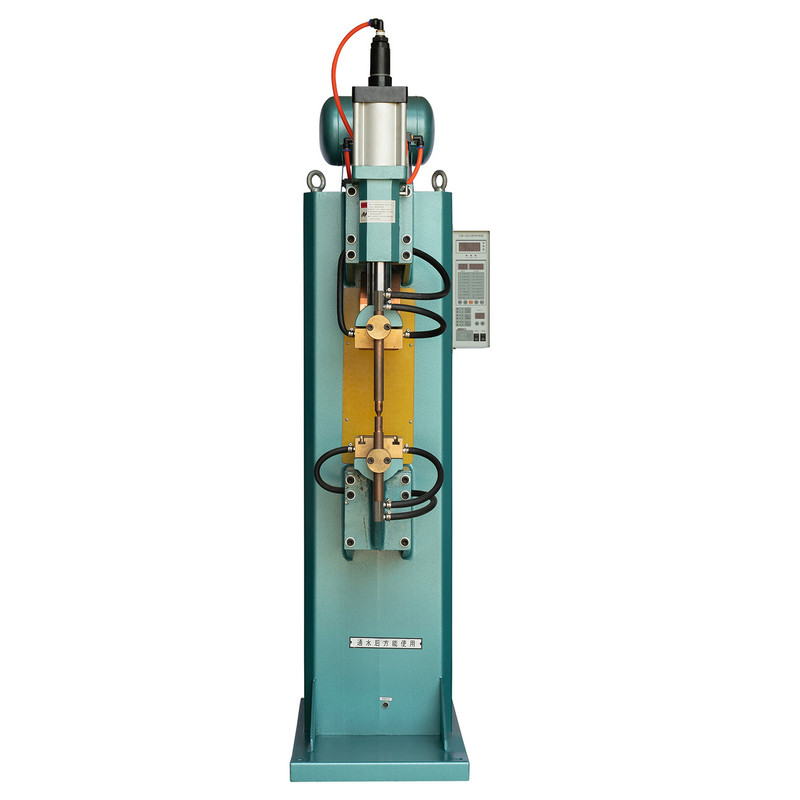

- Build quality: A sturdy frame and reliable components ensure long-term use.

- Ease of maintenance: Machines designed for straightforward upkeep reduce downtime.

By considering these aspects, wholesalers and end buyers can make informed decisions and select equipment that best matches their production goals.

The Relationship Between Welding Time and Material Properties

Different materials respond uniquely to heat and pressure. Thin sheets require shorter welding times , while thicker or harder metals need longer cycles. Adjustable welding time allows operators to tailor settings precisely to each material.

This adaptability improves weld penetration, minimizes surface damage, and ensures strong joint integrity . For businesses working with varied materials, such flexibility is indispensable.

Long-Term Value of Adjustable Welding Time

Beyond immediate production benefits, the adjustable welding time pedal spot welding machine also offers long-term advantages. Consistency in weld quality enhances customer satisfaction, while reduced defects lower warranty claims. Over time, these benefits build a strong reputation for reliability, which is crucial for both manufacturers and wholesalers.

Additionally, machines with adjustable features tend to stay relevant longer, as they can adapt to new materials or updated production requirements without needing complete replacement. This adaptability translates into a more sustainable investment.